What does it mean for you as a luminaire manufacturer?

Stefan Larsson, August 12, 2025

Summary

Lighting – a crucial but often overlooked technology in the EU’s green transition

As Europe transitions towards a greener and more competitive future, energy-efficient technology plays a key role. It drives innovation, creates jobs, strengthens industry – and reduces both energy costs and emissions.

Lighting, however, is often taken for granted. We turn it on and off without a second thought. Yet the right lighting not only contributes to safety and comfort – it is also one of the most cost-effective ways to reduce energy consumption.

With building automation, smart energy monitoring, and lifecycle optimisation in focus, the light source has become an active part of the digital ecosystem. Optoga’s DimIn DALI Memory brings smart functionality directly into the LED module – with no external driver.

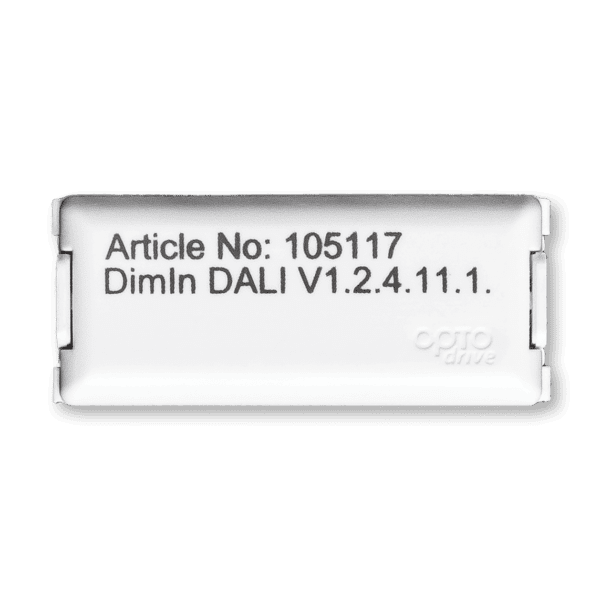

This document explains how DimIn DALI Memory uses parts of the DALI-2 standard (IEC 62386-251, -252, -253) to give manufacturers and integrators access to valuable data – while deliberately avoiding the “D4i” trademark to meet brand and certification requirements.

What is DimIn DALI Memory?

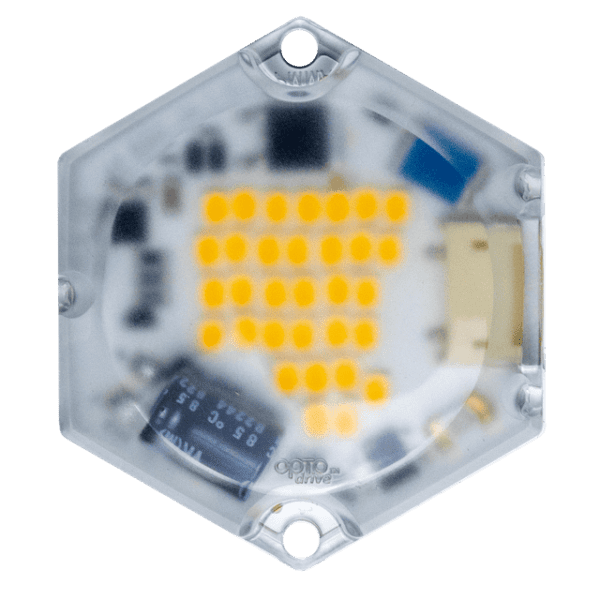

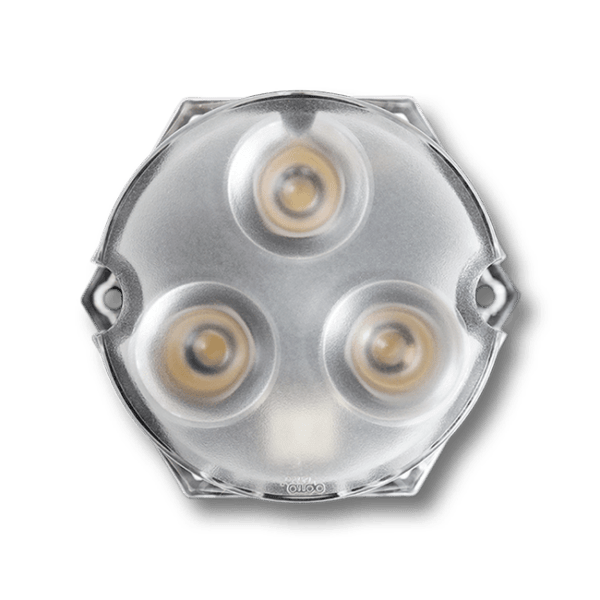

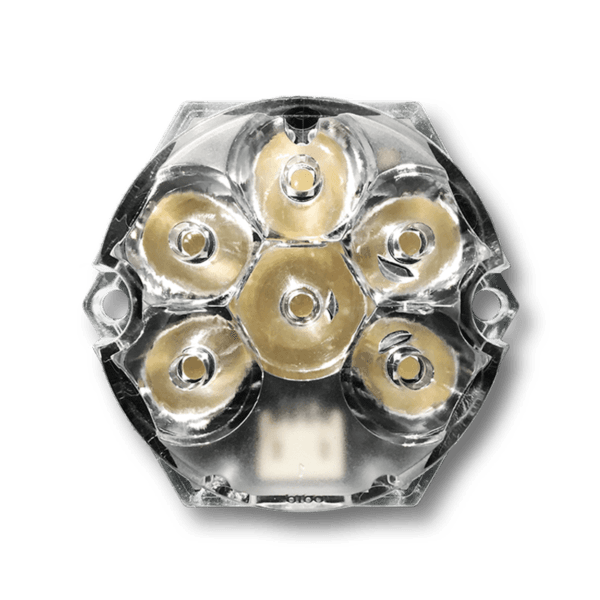

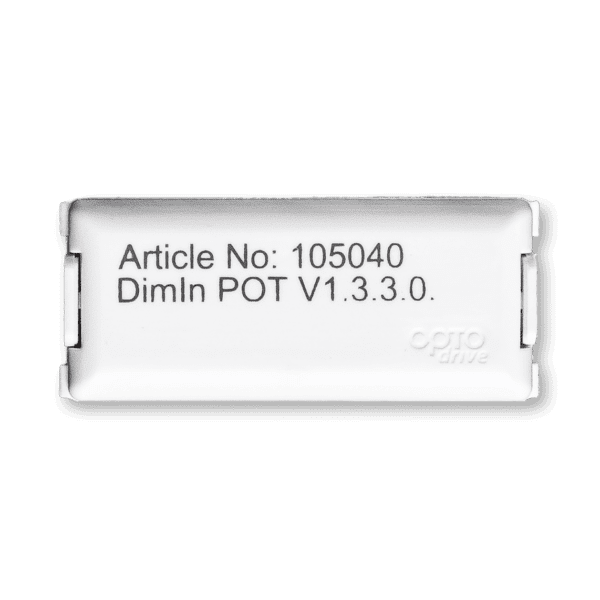

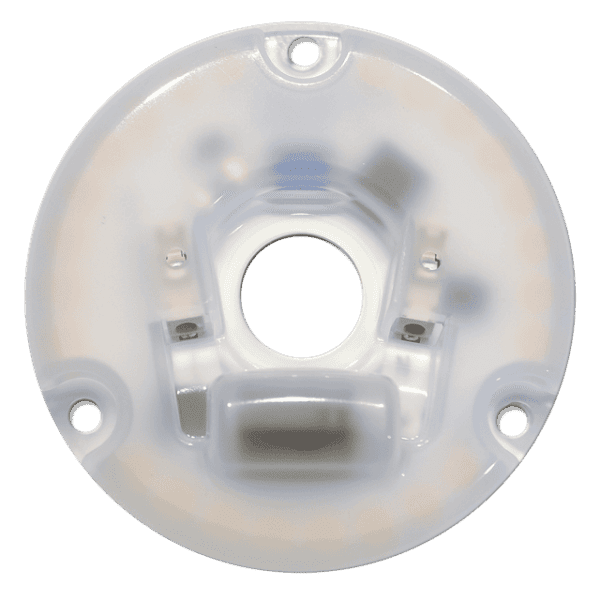

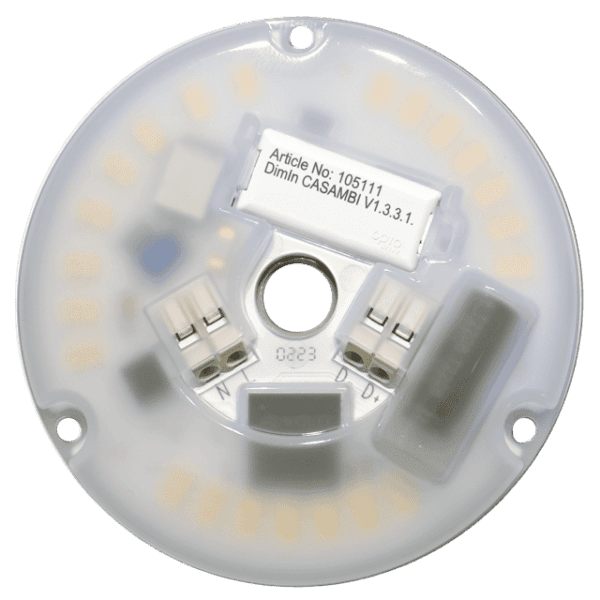

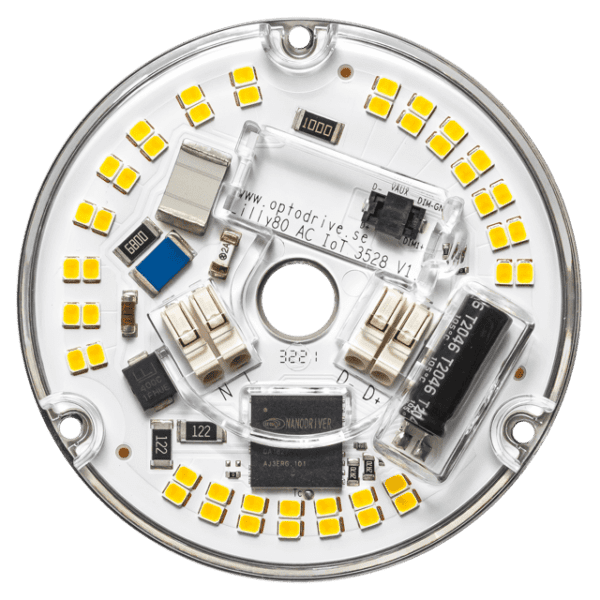

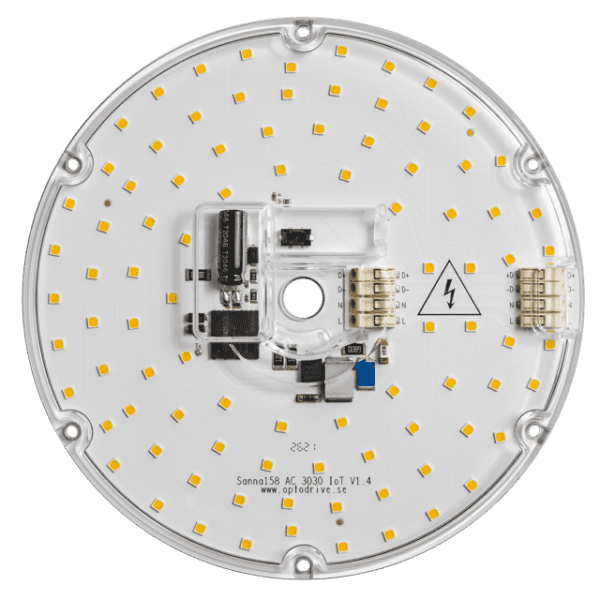

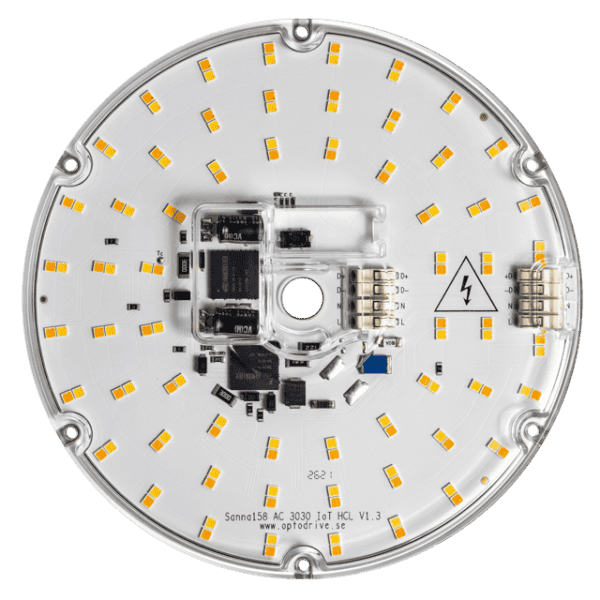

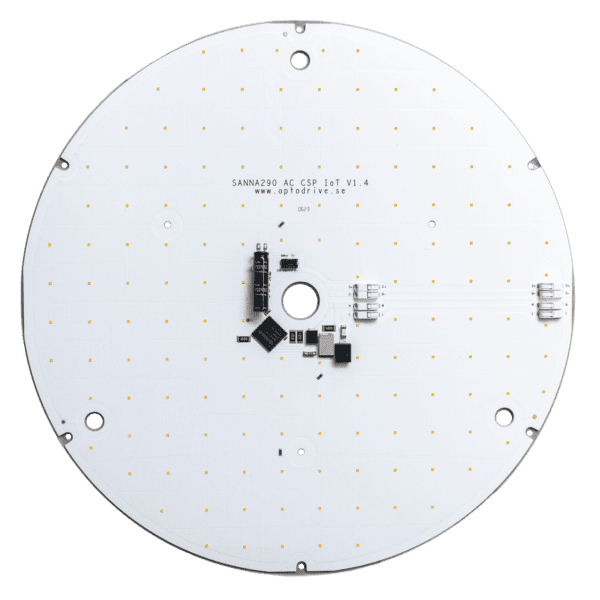

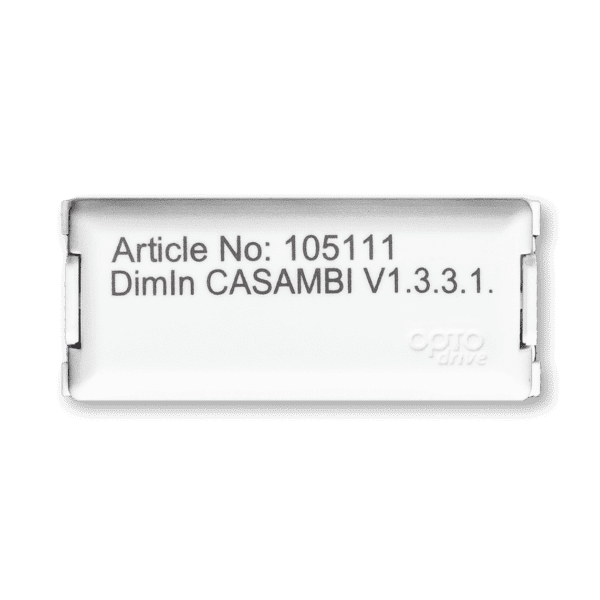

DimIn DALI Memory is Optoga’s integrated control interface enabling advanced monitoring and control directly in our IoT-ready LED modules. Without a separate driver, the module can be connected directly to DALI systems, Bluetooth (Casambi, Ingy), or simple control via potentiometer or push button.

The core of DimIn DALI Memory is support for three key parts of DALI-2:

- Luminaire Data (IEC 62386-251)

- Energy Metering (IEC 62386-252)

- Diagnostics (IEC 62386-253)

What makes DimIn especially powerful is the combination of static and dynamic data handling. Fixed information – such as luminous flux, colour temperature, production data, and optical configuration – is stored directly in the LED module. The DimIn unit reads this information via a data bus and combines it with real-time operational data such as temperature, power consumption, operating hours, and system status.

The system is only activated and able to generate diagnostics and energy reporting (per 252 and 253) once DimIn is installed.

Luminaire Data (Part 251)

Gain precise control over what is installed:

- Rated luminous flux (lm)

- Colour temperature (CCT) and colour rendering (CRI)

- Power class

- Optics and beam angle (configurable)

- Model ID and firmware version

This simplifies inventory management, unifies documentation, and provides certainty in design and procurement.

Energy Metering (Part 252)

Get insight into energy consumption per luminaire:

- Active power (W)

- Apparent power (VA)

- Power factor

- Operating hours (for energy declarations)

Ideal for creating energy reports, tracking deviations, and meeting EU energy directive requirements.

Diagnostics (Part 253)

Take control of maintenance – before anything fails:

- Internal temperature monitoring

- Operating hours counter

- Last known status before power loss

- DALI error reports (e.g., overheating or component failure)

Diagnostic data enables predictive maintenance and planned service interventions.

Why We Don’t Use “D4i

“D4i” is a registered trademark of the DiiA and may only be used by manufacturers whose components are certified to their specifications. Optoga’s solution is built on the open parts of IEC 62386, delivering compatible functionality without using the trademark.

Additionally, D4i includes an interface for powering and communicating with external sensors – something mainly relevant for outdoor luminaires. This interface is not included in Optoga’s solution, which is optimised for indoor applications where integration and simplified construction are more important than extended external connections.

We therefore call our implementation DimIn DALI Memory, and clearly document support for:

- 251 (Luminaire Data)

- 252 (Energy Metering)

- 253 (Diagnostics)

This ensures our customers can safely use DimIn in DALI-2 environments without confusion over certification.

Energy Efficiency & Control

From 2028, all new public buildings in the EU must meet the requirements for Zero Emission Buildings (ZEB). From 2030, the same applies to private buildings. The revised EPBD Directive (2024/1275) also requires buildings to be prepared for Building Automation and Control Systems (BACS) and to report energy data to support SRI scoring and ESG reporting.

With DimIn DALI Memory, lighting becomes an integral part of the building’s digital ecosystem. By supporting DALI-2 parts 251–253, the luminaire provides:

- Real-time measurement of energy and power

- Diagnostics for predictive maintenance

- Data transparency for BACS integration and EPBD reporting

For luminaire manufacturers, this means products can already meet upcoming requirements – without complex retrofitting or additional wiring.

EPBD in Practice

In practice, lighting solutions with real-time monitoring and smart control will be central components in EPBD-compliant buildings. These requirements include:

- Zero Emission Buildings (ZEB) from 2030 (2028 for public buildings)

- Energy reduction in the existing building stock, especially for low energy class buildings

- Lifecycle analysis and GWP reporting for new buildings over 1000 m² from 2028

- Requirements for solar readiness and EV charging infrastructure

- Digital energy data to support renovation plans and climate work

With DimIn DALI Memory, these requirements become an opportunity – not a technical burden. The luminaire becomes a data source. Power, temperature, lifetime parameters, and fault status are no longer hidden, but can be used for EPBD-related reporting, follow-up, and lifecycle optimization.

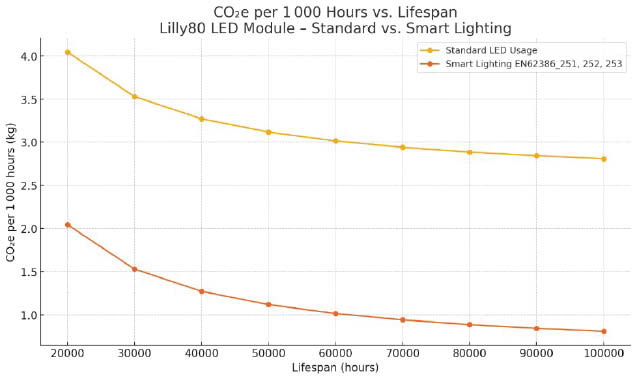

By reducing the output in the application, thermal stress on components is lowered, which can increase service life and reduce resource consumption. This results in a more sustainable and flexible use of luminaires over time – where lifespan is not fixed, but influenced by usage patterns and control strategies.

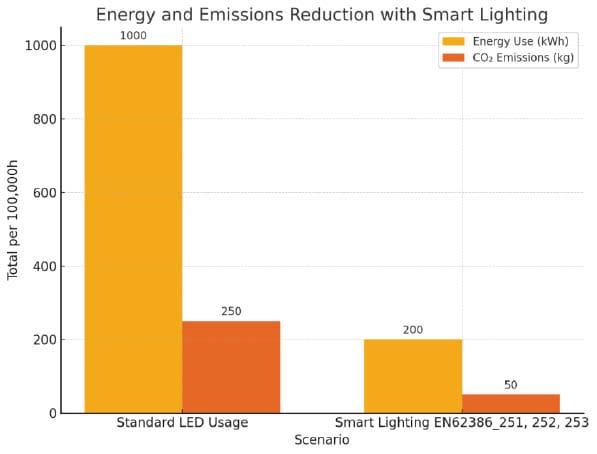

Industry Study Results

Intelligent lighting control with real-time analysis can reduce actual energy consumption by up to 80% compared to constant operation.

This means that an LED module that theoretically consumes 1,000 kWh over its lifetime can, in practice, be reduced to only 200 kWh – with a corresponding reduction in CO₂e emissions.

With built-in energy metering functionality, these savings become traceable, measurable, and reportable – supporting climate and energy declarations for building projects.

Installation Advantages

- No external driver: All DimIn modules operate directly on 230VAC.

- Flexible control: Compatible with DALI, Casambi, Ingy, 1–10V, Switch, and POT.

- Hot-swappable: Control system choice can be made during or after installation.

- Minimal flicker: <3% even at low dimming (Normal operation <1%).

- Fast startup: Communication available immediately upon power-up.

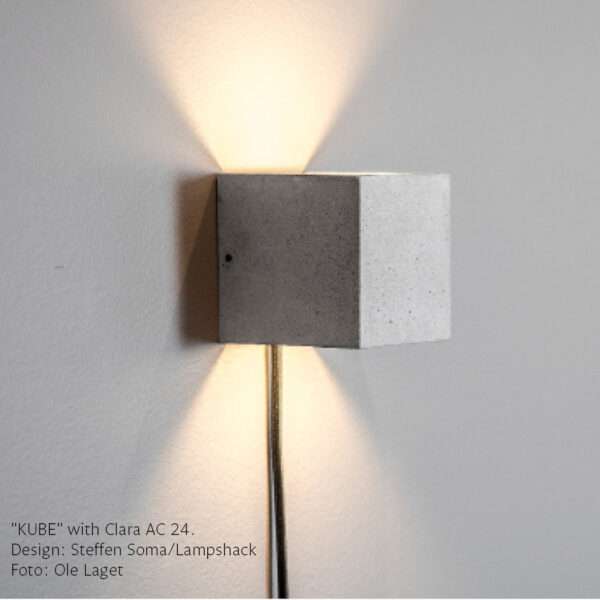

Typical Applications

- Office environments with real-time energy monitoring

- Hotels and restaurants

- Retail spaces

- Industrial lighting where maintenance requires planning

- Properties prepared for “Fit for 55”

Conclusion: Future-Proof Smart Lighting

DimIn DALI Memory enables smart, data-driven lighting systems – without added complexity. By integrating DALI-2 parts 251, 252, and 253 directly into the LED module, Optoga offers:

- Lower installation costs

- Better lifecycle management

- Real-time data for optimised operation

DimIn reads and uses static module data from the LED module and combines it with live measurements during operation. All functionality is built in – but requires DimIn to be installed.

This is smart lighting – built from the inside out.

With support for energy metering, diagnostics, and automated control, luminaires with DimIn not only contribute to reduced energy consumption but also to compliance in future-ready buildings. Our solution enables Fit for 55 requirements and makes it easier to achieve EPBD 2024/1275 compliance through measurability, traceability, and integration with modern BACS/BMS systems.

For integration guidance, demo modules, or more information, contact Optoga.

info@optoga.com

info@optoga.com +46 589 490 950

+46 589 490 950

info@optoga.com

info@optoga.com +46 589 490 950

+46 589 490 950